|

|

BIO

Dailey Engineering

specializes in custom Dry Sump Oil Pumps, with Roots

Style scavenge rotors and spur gear pressure sections, for

all levels of racing engines. Our Founder, Bill

Dailey, has been active for over 30 years in the

design of racing engines. With the design of several world class racing engines

under his belt, he now focuses his attention specifically to Dry Sump oil systems.

|

|

After graduating from college with a degree in mechanical

engineering, Bill Dailey followed

his father's words of advice simply put "if you don't follow your dream now you probably never

will". This advice to follow his passion for designing

racing engines has lead him to where he is today as the leader in custom made dry

sump oil systems.

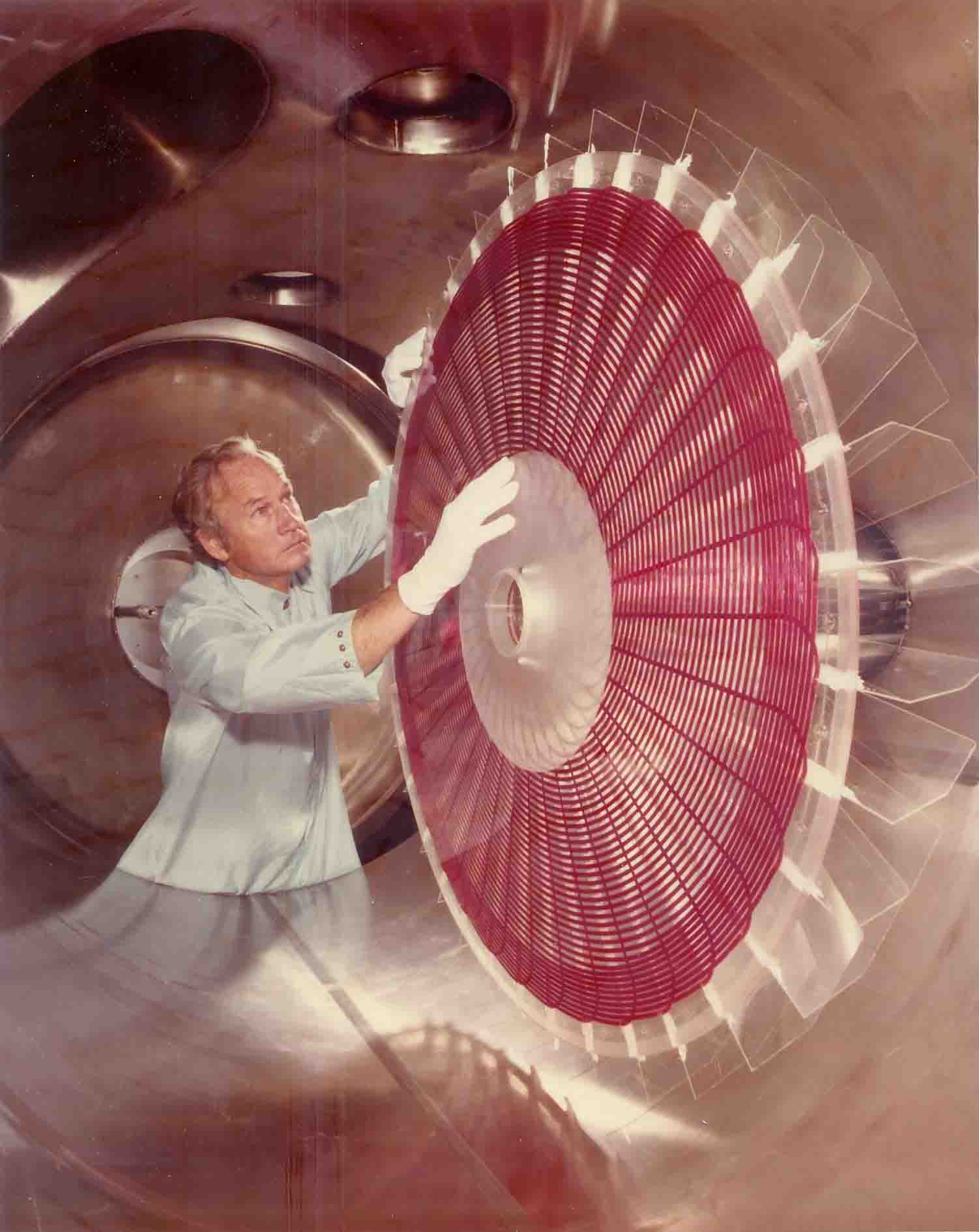

Bill learned about state of the art design from his father,

Dr Charles Lee Dailey, who

was a pioneer in the field of space propulsion shown here

with his Pulsed Inductive Thruster in a

vacuum test chamber. |

| |

|

When Electramotive

Engineering Inc. was purchased

by Nissan Motorsports and the newly formed (NPTI) Nissan Performance

Technology Inc. was created, Bill was placed in charge of the CNC

department. It was during this period of time Bill honed his

ability to rapidly prototype parts. It was not uncommon for a

sketch on a napkin to show up Friday from the race track from the

likes of Don Devendorf or Trevor Harris with a request for the part to

show up on Saturday. These rapidly designed and manufactured

parts were often used that weekend and one of the key's to

the success of the Nissan GTP program. We miss the day

of the true prototype race car... |

|

Bill took

a leave of absence from NPTI at which time Dailey

Engineering was formed as an engineering consulting firm.

Bill was contracted by TMAG to help design a Nissan Class 1 desert truck.

Bill

designed a state of the art driveline using a hewland transmission

coupled with a torque converter and adapted a 4 wheel drive

transfer case onto the back of the transmission. Today, Dailey

Engineering supplies torque converter oil pumps to

numerous off road racing teams who now couple their manual transmissions

with torque converters.

|

|

|

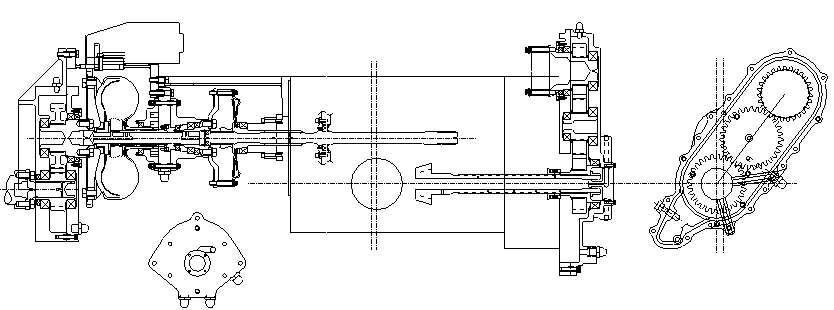

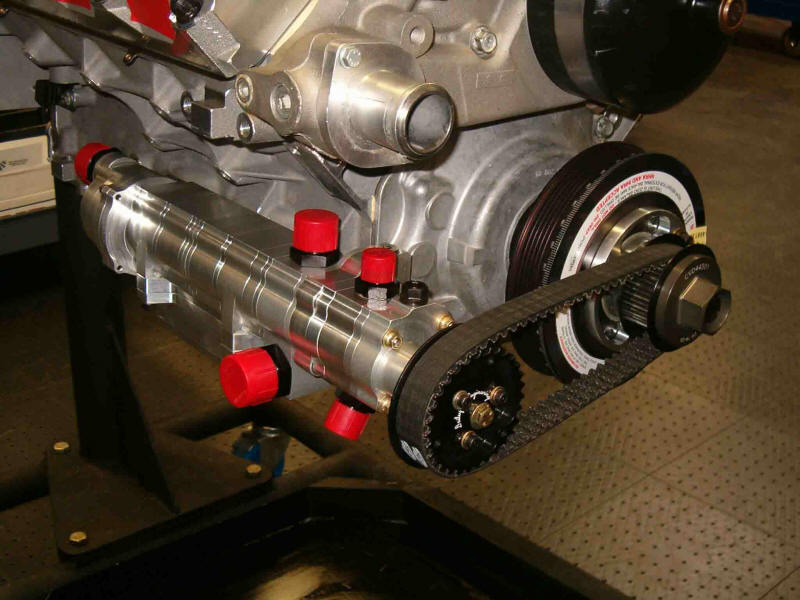

"Signature Series" LS 1

billet dry sump oil pan with 5 stage air/oil separator dry

sump oil pump and integral torque converter oil pump.

LS Oil Pan

|

|

On returning to NPTI, Bill was

assigned the lead engineering position under the direction of

Trevor

Harris on the Nissan Group C car. Along with overseeing all

aspects of the design, Bill was specifically responsible with the

front portion of the cars design along with the engine integration.

To test the V12 engine supplied by Nissan, Bill had the task of splicing an

Indy car in 2 and squeezing in the V12. |

|

|

|

When

Nissan Motorsports pulled out of racing in the early 90's, Bill

returned back to the sister company Electramotive Inc.. An

airplane retro was in the works with the installation of a

small block Chevy. Bill designed the prop reduction

chain drive unit. He was later contracted to work and

live in New Zealand to oversee the final phase of the

installation design work

on site. |

|

Upon

returning from New Zealand, Bill started working for

Caldwell Development Inc. and returned back to his roots as an engine designer. The most

significant and successful engine design would be the Dodge

Viper GTSR V-10. This engine was used in

numerous 24 hour endurance victories along with

championships around the world. Dailey Engineering was

later contracted by Chrysler to supply our "signature series"

dry sump oil pan with integral dry sump oil pump.

We still supply dry sump systems for the most recent

evolution of engine all over the world. Upon

returning from New Zealand, Bill started working for

Caldwell Development Inc. and returned back to his roots as an engine designer. The most

significant and successful engine design would be the Dodge

Viper GTSR V-10. This engine was used in

numerous 24 hour endurance victories along with

championships around the world. Dailey Engineering was

later contracted by Chrysler to supply our "signature series"

dry sump oil pan with integral dry sump oil pump.

We still supply dry sump systems for the most recent

evolution of engine all over the world.

Viper GTSR |

|

The next phase in Bill's career would

steer him away from racing for the first time. In parallel to

starting the design work that became the core of Dailey Engineering's

success, Bill was employed by General Atomics Aeronautical division.

Bill worked with a team to design a 3 cylinder, 6 opposed piston, 2

stroke diesel engine. blah blah blah, lets go racing... |

|

With the

design of a new oil pump and orders starting to come in it

was time to devote Bills full time energy to Dailey

Engineering.

Dailey

Engineering, the Custom Made Roots Style Dry Sump Oil Pump

company was well on its way...

And now...

Dailey Engineering

is the leader in the

industry for innovation, quality and customer service. |

|

|